Sunaero Americas earned the EASA Part-145 approval certificate!

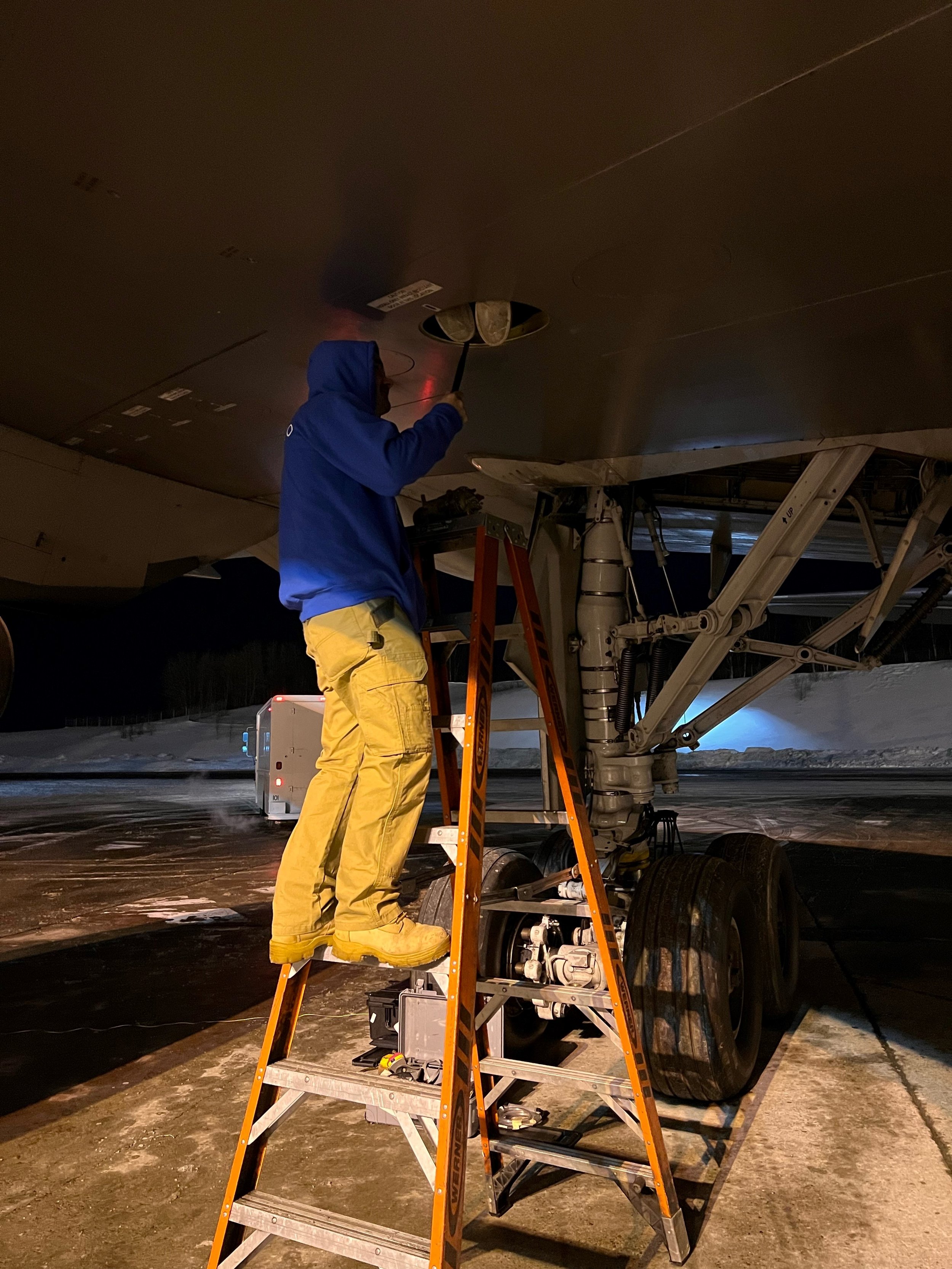

Not rain, nor sleet, nor snow limits our AOG teams from getting a plane back in the air. →

Bright and early into the new year we traveled to Anchorage, AK to repair a leaking AUX fueling valve on a 767 parked on a frigid ramp.

Read MoreAerowing designs a Rapid Desealing System kit for Navy P-8 community ( PN RD-S-NAV ). After testing and approval, each Navy P-8 location have been equipped with safe and effective sealant removal tools.

Read MoreDassault F8X Mod at Reno Service Center

Sunaero Americas successfully completed Dassault F8X Modification TI7X-M1949C-M. This was the first time our US team fully performed this mod. Scheduled completion was 10 days. We completed the task in just 3 thanks to our diligent and detail oriented mechanics.

Desealing, cleaning, sealing, painting, Curing and Leak Testing have also been performed on this job.

MRO Americas

Special thanks to everyone who came out to discuss advancements in aviation repairs & maintenance with us. For follow up inquiries contact Jenn Harding, jenn.harding@aerowing.com and Mark Johnson, mark.johnson@aerowing.com.

Straight Up Paint: MRO Links Digital Extra

A sufficient paint job isn't complete without total coverage, and this topic has a lot of layers.

Read MoreNew Aircraft Sealant Removal Kit

Aerowing has added a new aircraft sealant removal kit to our catalog, which includes the Sunaero developed Disposable Manual Scrapers. The Rapid Desealing Full Kit (PN: RD-FK-1111, NNO: 5130-14-579-7260) is listed in Airbus SRM Task 51-76-12 and remains compliant with Boeing BAC5000 directive.

Common methods for removing sealant can include metal scrapers that cause long-term structural harm, and wooden tongue depressors which have been proven to be ineffective.

Aerowing medical grade thermoplastic tips have been tested for use on the aircraft structure, including on delicate primer. The results of these tests verify that no structural damage will result in the use of Aerowing desealing tools.

Our pneumatic Rapid Desealing System sealant removal device was designed to remove large areas of sealant quickly, without the factors of human stress and injury. Several interchangeable tips are available to make aircraft sealant removal in crevices, seams and clean up work easy and stress free.

Aerowing Manual Desealing System handle can be used with flat sealant scraper attachments or an extension shaft can be integrated to make dual-use of the Rapid Desealing System threaded tips.

Try Aerowing aircraft sealant removal scrapers out today and help reduce production flow and non-mission capable time. Our sales representatives are happy to discuss success stories and custom sealant removal solutions with you, day or night. Simply email support@aerowing.com or call us on our 24/7 hotline, 1 (866) 325-FUEL (3835).

Gulfstream Approved Supplier

Aerowing is pleased to announce achievement of Gulfstream approved supplier in the capacity and scope of Technical Support for on-wing fuel leak repairs.

Aerowing Rapid Response Teams are standing by 24/7 to assist you in decreasing standard process times or with a troubled repeat fuel leak. Call today: 1 (855) 325-FUEL

Aerowing ground breaking aircraft fuel leak repair processes and specialized equipment continue to impress manufacturers and MRO facilities alike. We are preparing to release several new products and process improvement developments in the coming months. Subscribe to our blog for the latest news.

AEROWING awarded $2.6M ANG hydrogen leak detector contract

FOR IMMEDIATE RELEASE

1/13/15, Las Vegas, NV, Aerowing released today that they have been awarded a 5-year, $2.6 Million contract to provide the US Air National Guard with their HyTracker hydrogen leak detectors. The leak detectors will be supplied to improve the fuel leak detection process on F-16 fighter jets. First deliveries are expected to take place in Spring 2015.

Mike Evans, Executive Vice President of Aerowing says, “For decades, aircraft fuel leaks have been troubleshot the same way (soap and bubbles). The HyTracker will modernize the process of fuel tank maintenance and is a big step forward in reducing aircraft downtime.”

Aerowing is the industry leader in providing the United States Air Force, and its allies, with leading edge equipment and processes for fuel leak detection and repair.

For more information visit www.aerowing.com, or email support@aerowing.com

Master Sgt. Jeffrie Gardner, 1st Special Operations Component Maintenance Squadron accessories flight chief, displays the newly acquired Tank Pressurization System2 for use on C-130 aircraft.

Modernizing the war fighter

1st Special Operations Component Maintenance Squadron at Hurlburt Field AFB, FL have recently received a Helitest Wing Kit and Tank Pressurization System2 for fuel leak detection and fuel cell pressure decay and repair verification testing. MSgt. Jeffrie Gardner, the squadrons accessories flight chief, aided United States Air Force wide maintenance modernization by having C-130 fuel leak repair procedures updated to include efficiency and safety improvements. MSgt. Gardners goal in revising existing procedures was to update the way that scheduled and AOG maintenance is performed for Air Force Special Operations Command C-130 aircraft, to allow for increased aircraft availability for training missions.

Aircraft fuel leak detection processes, when Aerowing equipment is used, can save costly resources such as time and man power. Each control panel is operated by a touch screen program, nearly automating the leak detection, sealant curing and pressure decay tests.

Credit and the entire store of the improvements being made at Hurlburt AFB can be found on the Hurlburt AFB websites new page, or by clicking this link.

Thinking outside of the box

Last Friday Aerowing unveiled an updated look. Modern, high-tech and user-friendly compliment a new endeavor, expanding beyond the niche market of aircraft fuel leak detection and repair. Our highly experienced field staff and forward thinking engineering teams have partnered with some of the industries finest to adapt and modernized our ground support equipment into rapid repair and verification solutions for applications big and small. From fighters and carriers, to commercial and business jets and every where in between.

Aerowing.com now boasts streamlined icons helping customers to quickly locate solutions to modernize their aircraft maintenance and aircraft production processes. Need a helium leak detector for hydraulic systems, but also for fuel leak check? In search of a way to speed up windshield sealant curing, and also perform composite repairs? Simply follow the icons.

Thank you for checking out our new website. We hope that you will take some time and drop us a line. We'd love to hear from you, or show you how some of our ground support equipment can help you to optimize your aircraft maintenance or aircraft production.